Fat manufacture consists of a series of steps, each of which has a significant influence on the final characteristics of the products. In simplified terms, the production of a fat can be outlined in four main stages.

1. The mixture

The first step is to create the recipe. A margarine containing 80% fat, a pure fat, a mixture of vegetable oils with a certain percentage of water, a mix of animal and vegetable fats … the possibilities are endless. And this is clearly the basic property that will make the product more suitable for one application rather than another.

2. Crystallisation

Once the mixture is formed, it is pushed from the churning tank to its packaging line.

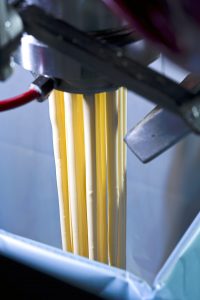

In the process, the fat, still warm and liquid, will be abruptly cooled by alternately passing through cold tubes, working tubes and resting tubes to gradually switch from a liquid to a solid state.

3. Packaging

Depending on the selected type of packaging, completely different behaviours can be observed, even if the starting recipe is absolutely identical.

4. Post-crystallisation

Once the product is packed and on pallets … it is often far from being ready to be delivered. Indeed, depending on the type of application, it is sometimes necessary to let the fat “mature” for a few days in our storage hall on the basis of highly specific temperature settings.

Once the product is packed and on pallets … it is often far from being ready to be delivered. Indeed, depending on the type of application, it is sometimes necessary to let the fat “mature” for a few days in our storage hall on the basis of highly specific temperature settings.

Once the product is packed and on pallets … it is often far from being ready to be delivered. Indeed, depending on the type of application, it is sometimes necessary to let the fat “mature” for a few days in our storage hall on the basis of highly specific temperature settings.